How a heat pipe-based tea drying system delivered environmental, health, and financial benefits in Brazil and the UK

| Leading University | Brunel University London |

| Location of impact | Brazil, UK |

| Thematic focus | Engineering |

| Funders | In Brazil: Ervateira São Mateus, SENAI. In the UK: Innovate UK, Solex Thermal |

| Partners | In Brazil: Ervateira São Mateus, SENAI. In the UK: Solex Thermal, Spirax Sarco |

Case study summary

Mate tea producers in Latin America have benefited from an innovative heat pipe-based drying system. Mate tea is a traditional herbal drink made from the leaves and stems of a plant native to South America. It is a popular drink in Argentina, Brazil, Paraguay and Uruguay, where some communities consume it more than coffee or other types of tea. Traditional drying methods for manufacturing mate tea can release high levels of polycyclic aromatic hydrocarbons (PAHs), known carcinogens also found in tobacco, affecting production line workers and consumers.

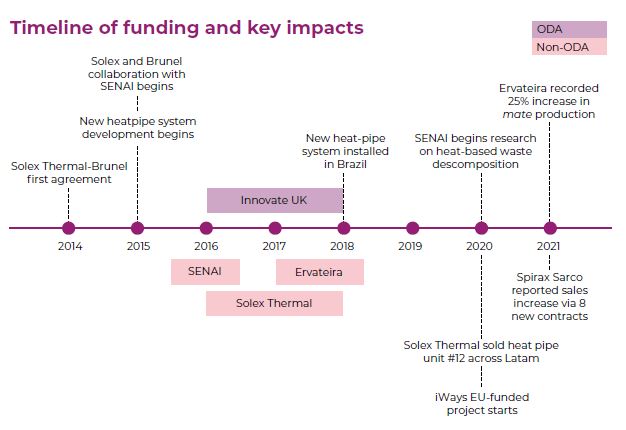

The innovative new system was developed by Brunel University’s Heat Pipe and Thermal Management Research Group and UK manufacturer Solex Thermal in partnership with the Brazilian Innovation Institute for Biomass (SENAI). Implemented in Brazil through a partnership with the local company Ervateira São Mateus, the project provided significant health, environmental, and financial advantages for mate manufacturers and consumers. These benefits, along with an economic analysis led by SENAI, helped mate tea reach new markets. The research also fostered technical innovation in Brazil.

In the UK, the system’s success boosted Solex Thermal’s expansion into the energy sector, leading to £12 million worth of heat pipe-based units across Latin America. The modular design and academic-industry collaborations further bolstered business partnerships, reputation and sustainability.

Primary benefits in Brazil and other Latin American countries

Healthier mate tea drying

The new method for drying matetea minimised health risks for Brazilian employees at Ervateira who were exposed to inhalation of PAHs in smoke. The changes in the production process also benefited an estimated 1,400,000 consumers by reducing the level of carcinogens, ensuring that mate met international standards.

Eco-friendly drying technology

The new technology made mate tea production more environmentally friendly. It reduced Ervateira’s carbon footprint associated with mate production

Growing business and commercial expansion

The app’s translation into English, French, Portuguese and Swahili facilitated its expansion to schools across Africa, to the benefit of over 270,000 children, mainly in Kenya and South Africa. The translation included cultural adaptations to ensure children accessed words and images relevant to them. Onebillion’s local partners in Brazil, Cambodia, India, and Jamaica have also implemented the app with small groups of students.

Local research capacity building in thermal technology

Working on the heat pipe technology improved technical skills and infrastructure for Brazilian researchers at SENAI and alsohelped kickstart new Brazilian-led research focused on heat-based waste decomposition.

Secondary benefits for the UK and Europe

Skill development in heat pipe technologies

Solex Thermal improved individual and organisational skills to create better, more eco-friendly heat pipe technologies. This helped the company secure a strong position in the competitive energy industry.

Heat pipe market growth

In less than 5 years, Solex Thermal sold 12 heat-pipe units across four Latin American countries, worth £12,000,000. Their parent company Spirax Sarco recorded £1,850,000 in new business. The success of the new heat-pipe system helped create 18 new jobs across the two collaborating UK companies.

Expanding the use of new technology

The easy assembly and modular design of the new heat pipe-based system facilitated scalability and expansion to meet the operational needs and specific application of other industries. This opened opportunities for UK manufacturers in the wider leaf-drying industry.

Strengthened academic-industry collaborations

Successful collaboration in the tea drying industry encouraged further Brunel-Solex Thermal joint initiatives on industrial-environmental challenges. Academics and professionals are working on iWays, a project co-funded by the European Union that aims to recover water and heat from various industries including waste management.

How secondary benefits unfolded

- Brunel University and Solex Thermal have a well-established and long-term academic-industry collaboration focused on identifying an industry challenge outside the UK and combining academic and private-sector expertise to tackle it. Both partners harnessed skills and lessons gained when developing the heat pipe drying system to contribute in the iWays project.

- The project highlighted potential applications of Solex Thermal’s technology in the leaf-drying industry. The new system’s demonstrable success led to reputational gains.

- The success of the new heat-pipe system boosted the expansion of Solex Thermal and Spirax Sarco products and services into the Latin American market.